2025 Zirconate-Based Solid Oxide Fuel Cell Manufacturing Report: Market Dynamics, Technology Innovations, and Strategic Forecasts. Explore Key Growth Drivers, Regional Trends, and Competitive Insights Shaping the Next Five Years.

- Executive Summary and Market Overview

- Key Technology Trends in Zirconate-Based SOFC Manufacturing

- Competitive Landscape and Leading Players

- Market Growth Forecasts and CAGR Analysis (2025–2030)

- Regional Market Analysis and Emerging Hotspots

- Challenges, Risks, and Market Entry Barriers

- Opportunities and Strategic Recommendations

- Future Outlook: Innovations and Long-Term Market Potential

- Sources & References

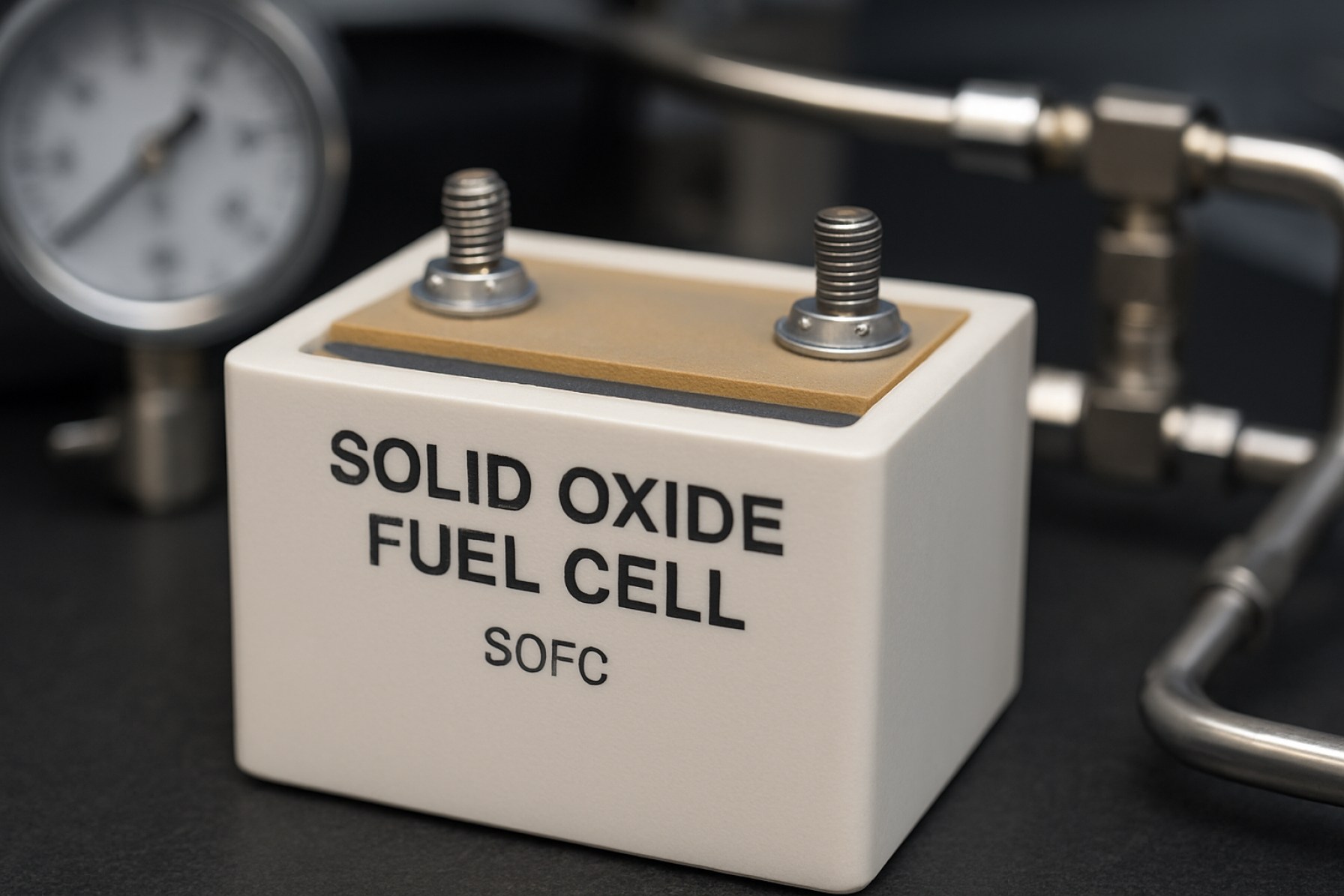

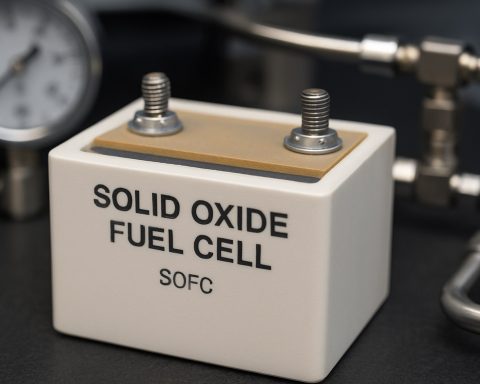

Executive Summary and Market Overview

Zirconate-based solid oxide fuel cells (SOFCs) represent a critical advancement in the field of high-temperature fuel cell technology, offering enhanced ionic conductivity, chemical stability, and fuel flexibility compared to traditional yttria-stabilized zirconia (YSZ) systems. As of 2025, the global market for zirconate-based SOFC manufacturing is experiencing robust growth, driven by increasing demand for efficient, low-emission energy solutions across stationary, portable, and transportation sectors.

The market is characterized by a surge in research and development activities, with leading companies and research institutions focusing on optimizing zirconate materials such as barium zirconate (BaZrO3) and strontium zirconate (SrZrO3) for improved proton conductivity and durability under operational conditions. These advancements are enabling SOFCs to operate at lower temperatures (500–700°C), reducing system costs and expanding application potential.

According to MarketsandMarkets, the global SOFC market is projected to reach USD 9.1 billion by 2027, with zirconate-based systems accounting for a growing share due to their superior performance in hydrogen and hydrocarbon fuel utilization. The Asia-Pacific region, led by Japan, South Korea, and China, remains at the forefront of both manufacturing capacity and deployment, supported by strong government initiatives and investments in clean energy infrastructure. Europe and North America are also witnessing increased adoption, particularly in distributed power generation and backup systems.

- Key Players: Major industry participants such as FuelCell Energy, Bloom Energy, and CeramTec are investing in zirconate-based SOFC technologies, aiming to enhance system efficiency and lifespan.

- Manufacturing Trends: The shift towards scalable, cost-effective manufacturing processes—including tape casting, screen printing, and co-sintering—is accelerating commercialization. Partnerships between material suppliers and system integrators are fostering innovation in cell design and stack assembly.

- Challenges: Despite promising growth, the market faces challenges such as high material costs, complex fabrication techniques, and the need for long-term durability testing under real-world conditions.

In summary, the zirconate-based SOFC manufacturing sector in 2025 is poised for significant expansion, underpinned by technological breakthroughs, supportive policy frameworks, and the global transition toward sustainable energy systems. Continued investment in R&D and manufacturing optimization will be pivotal in realizing the full commercial potential of zirconate-based SOFCs.

Key Technology Trends in Zirconate-Based SOFC Manufacturing

Zirconate-based solid oxide fuel cells (SOFCs) are at the forefront of next-generation energy solutions, and 2025 is witnessing several pivotal technology trends shaping their manufacturing landscape. These trends are driven by the need for higher efficiency, lower costs, and improved durability, as well as the push for scalable production to meet growing demand in stationary and mobile power applications.

- Advanced Sintering Techniques: Manufacturers are increasingly adopting advanced sintering methods such as spark plasma sintering (SPS) and microwave sintering. These techniques enable lower processing temperatures and shorter cycle times, which help preserve the fine microstructure of zirconate electrolytes and electrodes, resulting in enhanced ionic conductivity and mechanical strength. This shift is supported by research from Elsevier.

- Nanostructured Materials: The integration of nanostructured zirconate powders and thin films is improving the electrochemical performance of SOFCs. Nanostructuring increases the active surface area and promotes better interface contact between cell components, leading to higher power densities and longer operational lifespans. Companies like Tosoh Corporation are investing in scalable nanomaterial synthesis for SOFC applications.

- 3D Printing and Additive Manufacturing: Additive manufacturing is revolutionizing SOFC component fabrication by enabling complex geometries and reducing material waste. 3D printing of zirconate-based electrolytes and electrodes allows for precise control over porosity and thickness, which is critical for optimizing cell performance. GE Additive and other industry leaders are piloting these techniques for commercial-scale production.

- Automated Quality Control: The adoption of AI-driven inspection systems and real-time process monitoring is enhancing quality assurance in zirconate-based SOFC manufacturing. These systems detect microstructural defects and compositional inconsistencies early in the production process, reducing failure rates and improving yield, as highlighted by Siemens.

- Hybrid Manufacturing Approaches: Combining traditional tape casting with advanced co-sintering and infiltration methods is enabling the production of multi-layered SOFCs with tailored properties. This hybridization supports the integration of novel zirconate compositions and functional gradients, as reported by Fraunhofer Society.

These technology trends are collectively driving the evolution of zirconate-based SOFC manufacturing, positioning the sector for greater commercial viability and broader adoption in the global energy transition.

Competitive Landscape and Leading Players

The competitive landscape of zirconate-based solid oxide fuel cell (SOFC) manufacturing in 2025 is characterized by a mix of established multinational corporations, specialized energy technology firms, and innovative startups. The market is driven by the increasing demand for high-efficiency, low-emission energy solutions, with zirconate-based electrolytes and electrodes gaining traction due to their superior ionic conductivity and thermal stability compared to traditional yttria-stabilized zirconia (YSZ) materials.

Key players in this sector are investing heavily in research and development to optimize zirconate compositions, improve cell durability, and reduce manufacturing costs. Siemens Energy and Bloom Energy are among the leading companies integrating advanced zirconate materials into their SOFC platforms, targeting both stationary and distributed power generation markets. These firms leverage their extensive engineering capabilities and global supply chains to scale up production and deploy commercial systems.

In Asia, Mitsubishi Power and Fuji Electric are prominent, focusing on the development of high-performance zirconate-based SOFC stacks for industrial and utility-scale applications. Their efforts are supported by strong government initiatives promoting clean energy technologies, particularly in Japan and South Korea.

European players such as CeramTec and SolydEra are recognized for their expertise in advanced ceramics and fuel cell stack manufacturing. These companies are collaborating with research institutions to refine zirconate processing techniques and enhance the longevity of SOFC components.

- Bloom Energy: Pioneering commercial SOFC systems with ongoing zirconate material integration.

- Siemens Energy: Scaling up zirconate-based SOFCs for distributed energy solutions.

- Mitsubishi Power: Advancing high-capacity SOFC stacks for industrial use.

- CeramTec: Supplying advanced zirconate ceramics for SOFC manufacturers.

- SolydEra: Innovating in stack design and zirconate material processing.

The competitive environment is further shaped by strategic partnerships, joint ventures, and licensing agreements, as companies seek to accelerate commercialization and address technical challenges such as interfacial stability and cost-effective mass production. The sector is expected to see continued consolidation and collaboration as zirconate-based SOFCs move toward broader market adoption in 2025 and beyond.

Market Growth Forecasts and CAGR Analysis (2025–2030)

The zirconate-based solid oxide fuel cell (SOFC) manufacturing market is poised for robust growth between 2025 and 2030, driven by increasing demand for efficient, low-emission energy solutions across industrial, commercial, and residential sectors. According to projections from MarketsandMarkets, the global SOFC market is expected to register a compound annual growth rate (CAGR) of approximately 13–15% during this period, with zirconate-based variants gaining traction due to their superior ionic conductivity and thermal stability compared to traditional yttria-stabilized zirconia (YSZ) cells.

Key growth drivers include ongoing advancements in zirconate material formulations, which are enabling higher operating efficiencies and longer lifespans for SOFC systems. The adoption of these advanced materials is particularly notable in stationary power generation and distributed energy applications, where reliability and cost-effectiveness are paramount. Grand View Research highlights that the Asia-Pacific region, led by Japan, South Korea, and China, will be a major contributor to market expansion, owing to substantial investments in clean energy infrastructure and government-backed initiatives supporting fuel cell deployment.

By 2025, the market value for zirconate-based SOFC manufacturing is projected to reach approximately USD 1.2–1.5 billion, with a steady upward trajectory anticipated through 2030. This growth is underpinned by increasing commercialization of fuel cell systems for both grid and off-grid applications, as well as the integration of SOFCs in combined heat and power (CHP) systems. Fortune Business Insights notes that the transition toward hydrogen-based economies and the decarbonization of industrial processes will further accelerate demand for high-performance zirconate-based SOFCs.

- Projected CAGR (2025–2030): 13–15%

- Estimated market value by 2025: USD 1.2–1.5 billion

- Key growth regions: Asia-Pacific, North America, Europe

- Primary applications: Stationary power, distributed generation, CHP systems

In summary, the zirconate-based SOFC manufacturing sector is set for significant expansion through 2030, propelled by technological innovation, supportive policy frameworks, and the global shift toward sustainable energy solutions.

Regional Market Analysis and Emerging Hotspots

The regional landscape for zirconate-based solid oxide fuel cell (SOFC) manufacturing in 2025 is shaped by a combination of technological expertise, government policy, and supply chain dynamics. Asia-Pacific continues to dominate the market, with Mitsubishi Electric and Toshiba Energy Systems & Solutions Corporation leading large-scale SOFC production, particularly in Japan and South Korea. These countries benefit from robust R&D ecosystems, strong government incentives for clean energy, and established supply chains for advanced ceramics and rare earth materials essential for zirconate-based electrolytes.

China is rapidly emerging as a hotspot, driven by aggressive investments in hydrogen infrastructure and fuel cell technology. The Chinese government’s 14th Five-Year Plan prioritizes fuel cell vehicle deployment and domestic manufacturing of key components, including zirconate-based ceramics. Companies such as Sinopec and CeramTec (with joint ventures in China) are expanding their production capacities to meet both domestic and export demand.

In Europe, Germany and the Nordic countries are at the forefront, leveraging their advanced materials industries and strong policy support for decarbonization. Siemens Energy and Bosch are investing in pilot-scale zirconate-based SOFC lines, targeting distributed power generation and industrial applications. The European Union’s “Fit for 55” package and the Hydrogen Strategy are catalyzing public-private partnerships and cross-border projects, making the region a key innovation hub.

North America, particularly the United States, is witnessing renewed interest in SOFCs due to the Inflation Reduction Act and Department of Energy funding for clean hydrogen and advanced manufacturing. Bloom Energy and FuelCell Energy are exploring zirconate-based chemistries to improve durability and reduce costs, with pilot projects in California and Texas.

- Emerging Hotspots: India and Australia are gaining traction as new entrants, leveraging abundant raw materials and government-backed clean energy initiatives. Pilot projects in Gujarat and New South Wales are expected to scale up by 2026.

- Supply Chain Considerations: Proximity to zirconium and rare earth mineral sources is influencing site selection for new manufacturing plants, with Africa (notably South Africa) and Australia becoming strategic suppliers.

Overall, the regional market for zirconate-based SOFC manufacturing in 2025 is characterized by a shift toward Asia-Pacific and China, with Europe and North America focusing on innovation and pilot deployments, and new hotspots emerging in resource-rich regions.

Challenges, Risks, and Market Entry Barriers

The manufacturing of zirconate-based solid oxide fuel cells (SOFCs) in 2025 faces a complex landscape of challenges, risks, and market entry barriers that can significantly impact new entrants and established players alike. One of the primary technical challenges is the high sintering temperature required for zirconate ceramics, which often exceeds 1400°C. This not only increases energy consumption and operational costs but also demands specialized, high-durability equipment, raising the initial capital expenditure for manufacturers. Additionally, achieving consistent phase purity and microstructural control in zirconate electrolytes is critical for performance but remains technically demanding, leading to potential yield losses and quality assurance issues.

Material sourcing presents another significant barrier. High-purity zirconium compounds are essential for SOFC performance, but their supply chain is vulnerable to geopolitical risks and price volatility, particularly as major reserves are concentrated in a few countries. This can lead to unpredictable raw material costs and supply disruptions, complicating long-term planning for manufacturers (U.S. Geological Survey).

Intellectual property (IP) constraints also pose a risk. The field of SOFCs, especially those utilizing advanced zirconate chemistries, is heavily patented. Navigating this landscape requires significant legal resources and may necessitate licensing agreements, which can erode profit margins or even block market entry for new players (World Intellectual Property Organization).

From a market perspective, the high upfront investment and long development cycles for zirconate-based SOFCs deter many potential entrants. The need for extensive pilot testing, certification, and compliance with evolving environmental and safety regulations further extends time-to-market and increases costs. Moreover, the market is characterized by established partnerships between leading SOFC manufacturers and end-users in sectors such as distributed power generation and industrial hydrogen production, making it difficult for newcomers to secure initial contracts (Bloomberg).

- High sintering temperatures and energy costs

- Supply chain vulnerabilities for high-purity zirconium

- Complex IP landscape and potential legal barriers

- Significant capital requirements and long development cycles

- Stringent regulatory and certification demands

- Entrenched industry relationships limiting new market access

These factors collectively create a high barrier to entry for zirconate-based SOFC manufacturing in 2025, requiring substantial technical expertise, financial resources, and strategic planning to overcome.

Opportunities and Strategic Recommendations

The zirconate-based solid oxide fuel cell (SOFC) market in 2025 presents a range of opportunities driven by the global push for decarbonization, advancements in material science, and the growing demand for efficient, high-temperature energy conversion systems. Zirconate materials, particularly those based on barium zirconate and strontium zirconate, are gaining traction due to their superior ionic conductivity and chemical stability compared to traditional yttria-stabilized zirconia (YSZ) electrolytes. This shift opens several strategic avenues for manufacturers and investors.

- Material Innovation: Companies investing in advanced zirconate compositions can capitalize on the need for higher efficiency and longer-lasting SOFCs. Research collaborations with academic institutions and material science firms can accelerate the development of proprietary zirconate formulations, offering a competitive edge in performance and durability (International Energy Agency).

- Cost Reduction through Scale: As demand for SOFCs rises in stationary power, distributed generation, and auxiliary power units, scaling up zirconate-based cell production can drive down costs. Strategic partnerships with component suppliers and automation of manufacturing processes are recommended to achieve economies of scale (Bloom Energy).

- Targeting Emerging Markets: Rapid industrialization and electrification in Asia-Pacific and the Middle East present significant growth opportunities. Manufacturers should consider localizing production or forming joint ventures to navigate regulatory environments and reduce logistics costs (Wood Mackenzie).

- Integration with Hydrogen Infrastructure: The global hydrogen economy is expanding, with governments investing in hydrogen production and distribution. Zirconate-based SOFCs, with their high fuel flexibility, are well-positioned to serve as efficient power generators in hydrogen hubs. Strategic alliances with hydrogen producers and infrastructure developers can secure long-term demand (U.S. Department of Energy Hydrogen Program).

- Aftermarket Services and Lifecycle Management: Offering maintenance, monitoring, and upgrade services for deployed SOFC systems can create recurring revenue streams and strengthen customer relationships. Digital platforms for predictive maintenance and performance analytics are recommended investments (GE Digital).

In summary, the 2025 landscape for zirconate-based SOFC manufacturing is shaped by technological innovation, market expansion, and integration with the broader clean energy ecosystem. Companies that prioritize R&D, cost leadership, and strategic partnerships are best positioned to capture emerging opportunities and drive long-term growth.

Future Outlook: Innovations and Long-Term Market Potential

The future outlook for zirconate-based solid oxide fuel cell (SOFC) manufacturing in 2025 is shaped by a convergence of technological innovation, evolving energy policies, and increasing demand for efficient, low-emission power generation. Zirconate ceramics, particularly yttria-stabilized zirconia (YSZ), have long been the electrolyte of choice for SOFCs due to their high ionic conductivity and stability at elevated temperatures. However, ongoing research is driving the development of advanced zirconate materials with improved performance and manufacturability.

Key innovations anticipated in 2025 include the refinement of thin-film fabrication techniques, such as tape casting and chemical vapor deposition, which enable the production of thinner, more efficient zirconate electrolytes. These advances are expected to reduce operating temperatures, enhance durability, and lower overall system costs. Additionally, the integration of dopants and composite structures is being explored to further boost ionic conductivity and mechanical resilience, addressing some of the traditional limitations of zirconate-based SOFCs.

On the manufacturing front, automation and digitalization are set to play a pivotal role. The adoption of Industry 4.0 principles—such as real-time process monitoring, predictive maintenance, and data-driven quality control—will likely streamline production, minimize defects, and accelerate scale-up. Leading industry players, including Bosch and CeramTec, are investing in smart manufacturing facilities to meet the anticipated surge in demand for SOFC components.

Market potential for zirconate-based SOFCs is underpinned by global decarbonization efforts and the transition to distributed energy systems. According to MarketsandMarkets, the global SOFC market is projected to grow at a CAGR exceeding 10% through 2030, with zirconate-based systems capturing a significant share due to their proven reliability and performance. Applications are expanding beyond stationary power generation to include auxiliary power units, residential micro-CHP, and even transportation, as demonstrated by pilot projects from Siemens Energy and Bloom Energy.

In summary, the long-term market potential for zirconate-based SOFC manufacturing is robust, driven by material innovations, advanced manufacturing processes, and a favorable policy environment. Continued investment in R&D and production infrastructure will be critical to unlocking new applications and achieving cost competitiveness with alternative energy technologies.

Sources & References

- MarketsandMarkets

- FuelCell Energy

- Bloom Energy

- CeramTec

- GE Additive

- Siemens

- Fraunhofer Society

- Siemens Energy

- Fuji Electric

- SolydEra

- Grand View Research

- Fortune Business Insights

- Mitsubishi Electric

- Bosch

- World Intellectual Property Organization

- International Energy Agency

- Wood Mackenzie

- U.S. Department of Energy Hydrogen Program